Wax elements

WAX ELEMENT

Thermostatic elements convert change in temperature into mechanical motion. The expansion material is carefully obtain the required characteristics for each application. There are several ways the piston movement can be generated. The 3main technologies are know as « flat diaphragm », « squeeze push » and « annular / O’ring »

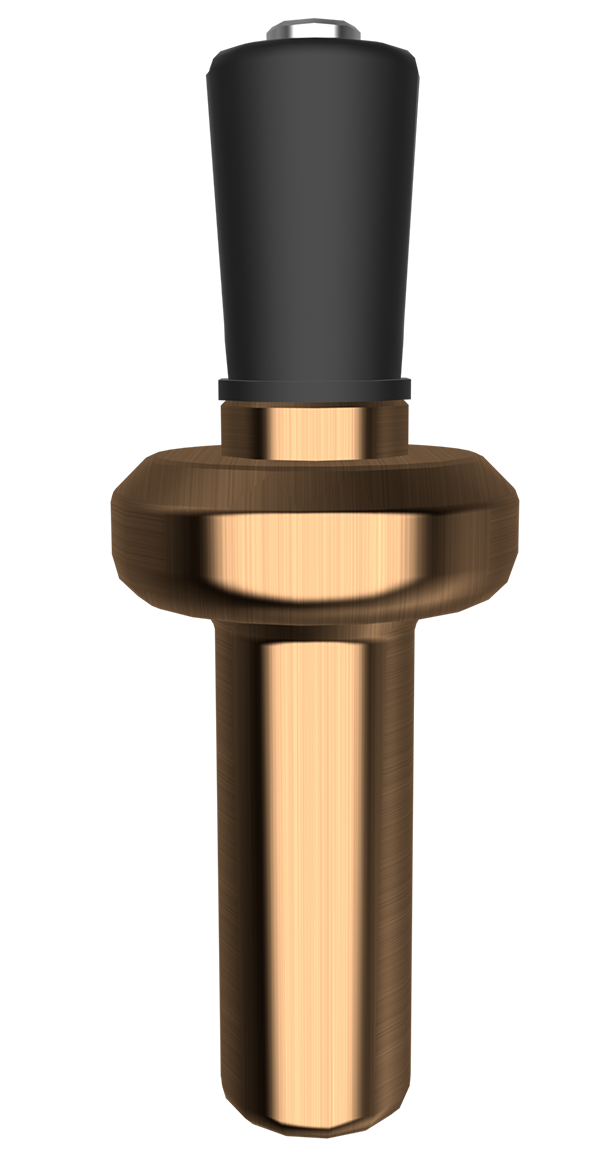

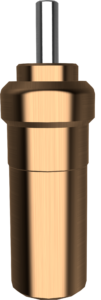

Flat diaphragm element

When heated the wax enclosed in the cup, expands and pushes against the diaphragm. The movement is transmitted via the plug to the piston. The guide maintains the diaphragm and allows the plug and piston to slide freely. An external spring ensures the return of piston when cooling down.

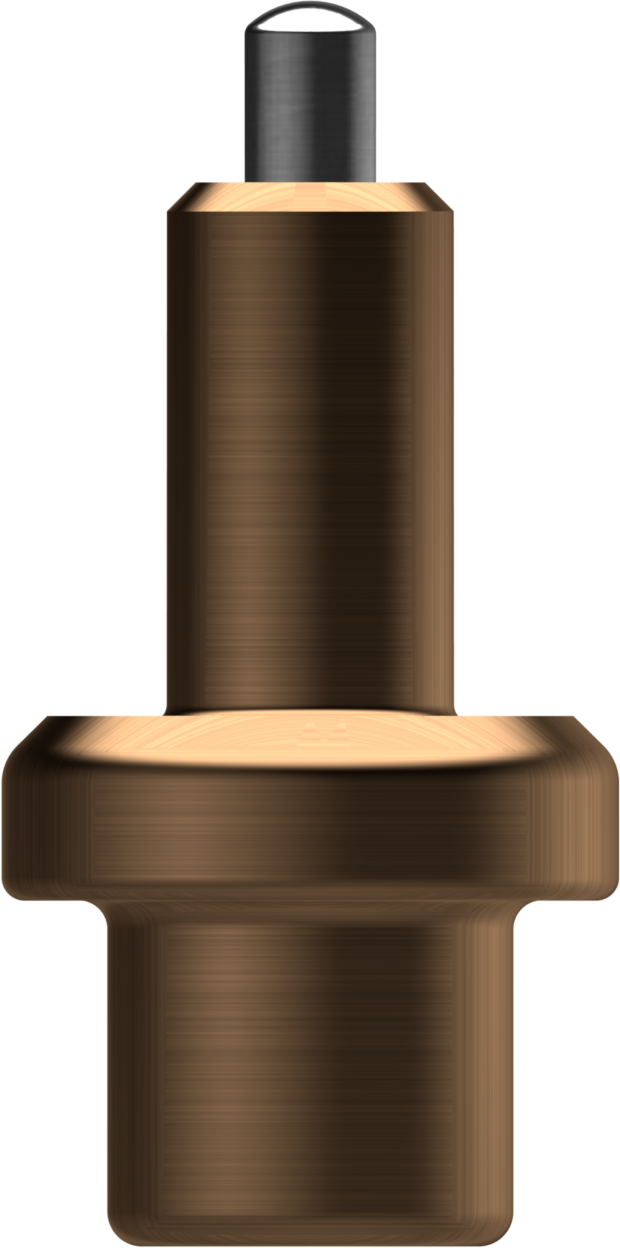

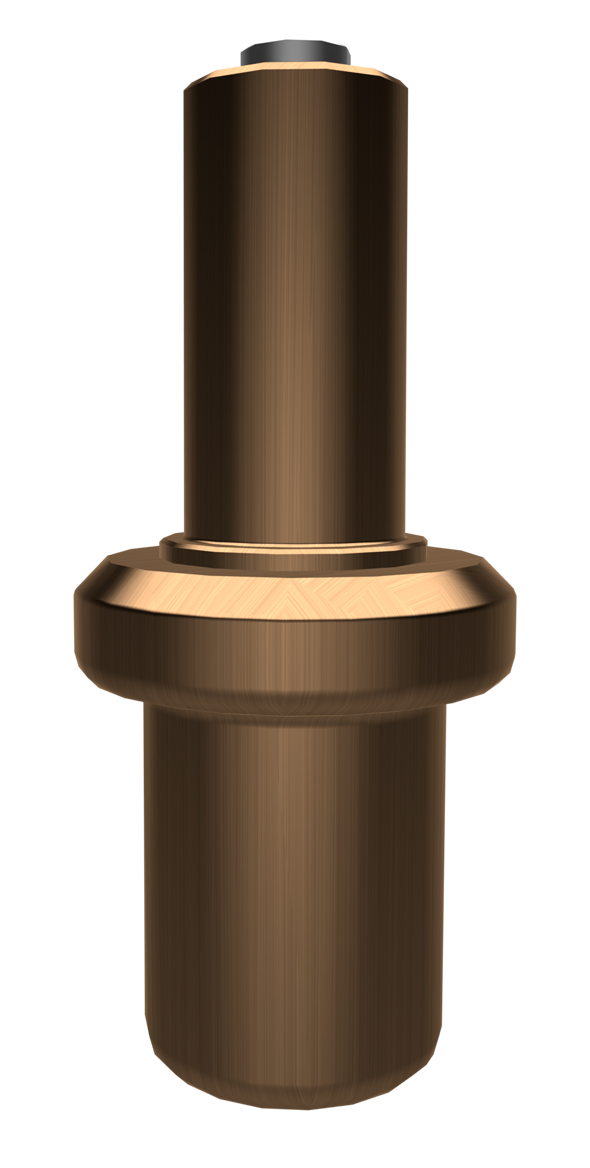

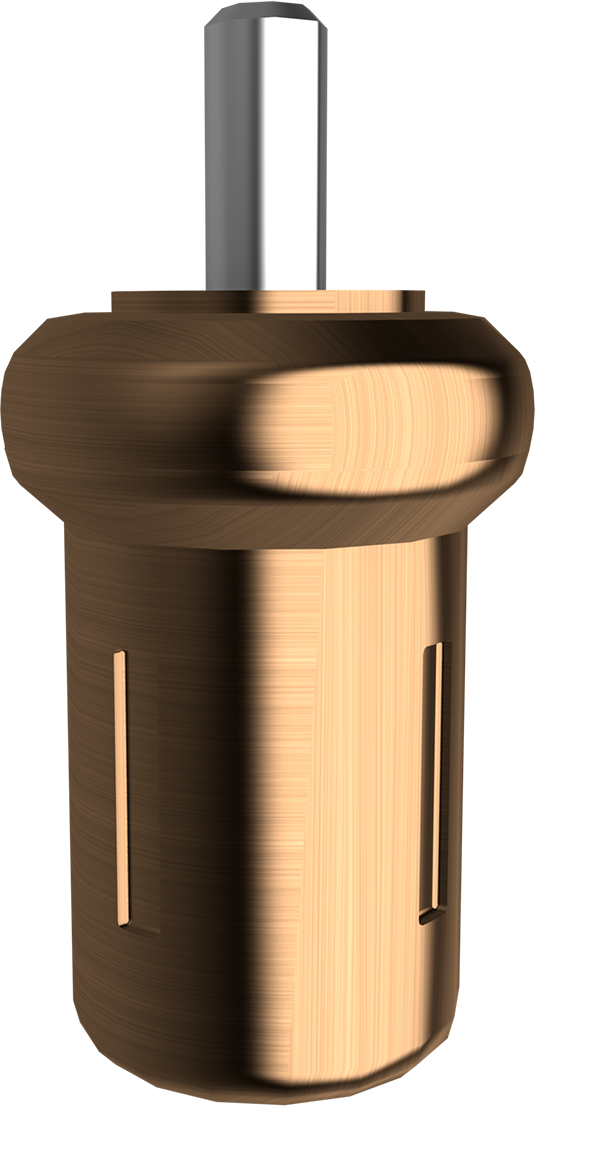

Squeeze-push elements

In this design, the piston is surrounded by an « elastomer bag ». When heated, the wax in the cup exands and pressure applies with the bag. Both radial force (squeeze) and an axial force (push) on the piston. Again, an external spring ensures the return of the piston when the temperature decreases.

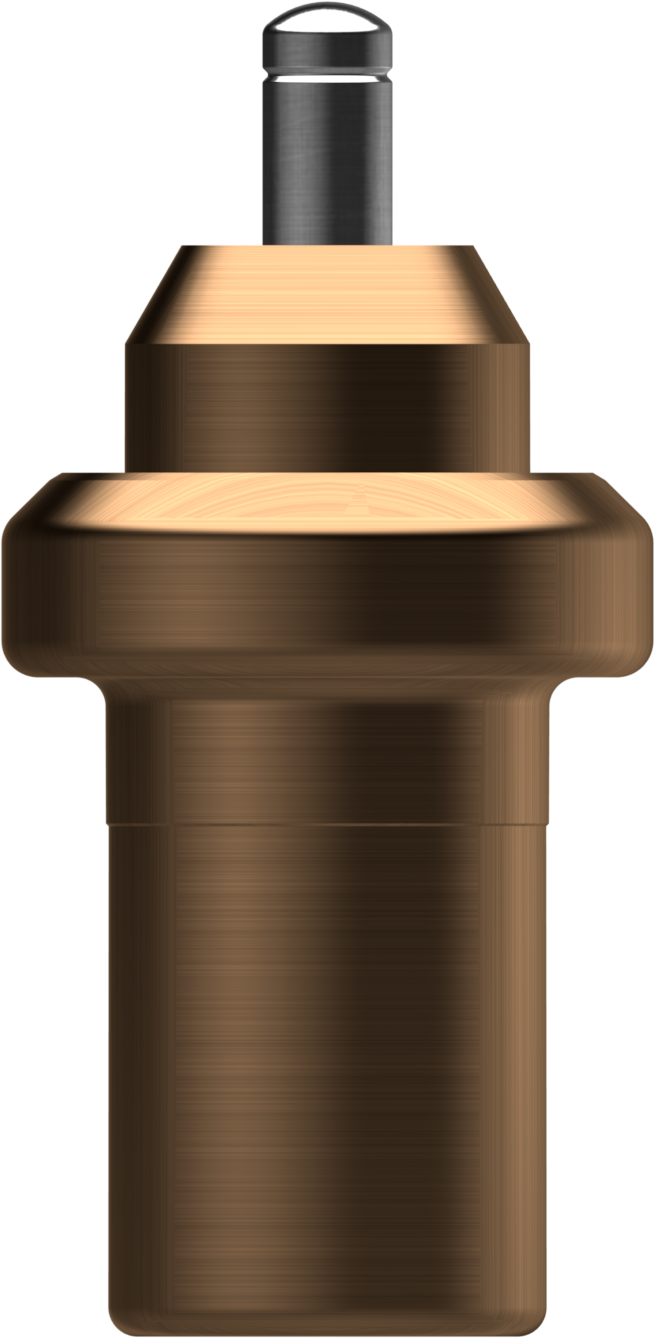

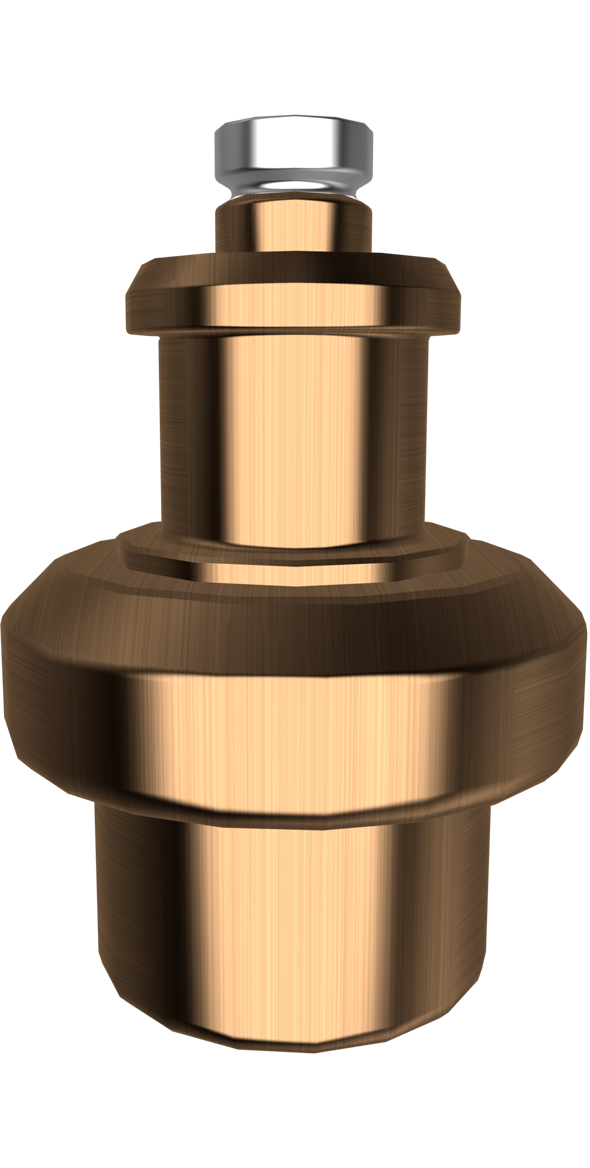

Annular element

An annular element is shaped with a ring diaphragm. It reacts to temperature changes by expanding or contracting, commonly used to regulate fluid flow or control thermal systems.

Flat diaphragm elements range

ø 10 MM

Load 40 Newton

ø 15 MM

LOAD 90 NEWTON

ø 18 MM

LOAD 180 NEWTON

ø 22 MM

Load 350 NEWTON

Squeeze-push elements range

ø 15 MM

LOAD 90 NEWTON

ø 18 MM

LOAD 180 NEWTON

Annular Element

ø 18 MM

LOAD 350 NEWTON

Our Solutions

Whatever your customers require, we have the solution ! Our thermostatic solutions have been the best on the market for almost a century. Let us show you why